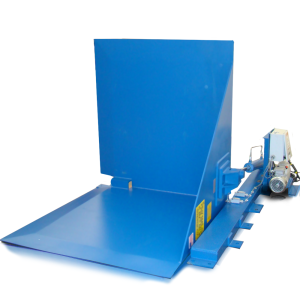

Low Duty Tippers

2,000 & 4,000 lb Capacity

Upending coils and rolls are tough—tough on your employees, tough on machinery and tough on the product. That’s why we developed our line of 90-degree low duty pallet tippers to provide securely anchored, highly-durable equipment that could take on that simple, yet arduous, task. Our pallet tippers and coil upenders are a great, safe alternative to a potentially dangerous and labor intensive operation. We offer four low duty pallet tipper design styles, all customizable to your specific roll/coil dimensions and weight.

Need a custom low duty tipper? Cherry's designs and builds to your specifications in 4-6 weeks. Contact us today for a free, no obligation quote on a high quality roll tipper!

Low duty Pallet Tipper Features

A pallet tipper helps to position product to either a horizontal or vertical position for use or storage. A simple and essential product that requires some thought and engineering before purchase. First would be the sizes and weights of the object, then does it fit within the machine’s capacities. Finally would be the ideal load in height and discharge height and the type of equipment used for load and unloading. Other features of our pallet tippers include:

-

Function

Safely tip coils, rolls, reels or boxes for storage, shipping or in plant use.

Rotate product within a 90-degree radius to change vertical/horizontal orientation for shipping or production.

-

Operation

Up and down push-button control pendant

4 different design types with multiple capacities

-

Safety

Maintenance locks

Line mounted CB valves to hold basket in place

Perimeter fencing and light curtains available

Special Order Modifications

Low Duty Pallet Tippers offer a huge advantage in decreasing the manual labor of shipping and distribution warehouse operations. We carry a number of different models of low duty pallet tippers that can serve the diverse needs of distribution centers and warehouse facilities. Our tippers offer benefits like faster cycle times, fewer accidents and injuries and better use of space, showcasing just a few reasons why pallet tippers are such a valuable asset to your facility.

At Cherry's Industrial our experts can help you find exactly what to look for in a pallet tipping machine that will be most impactful for your warehouse. We start by examining your existing warehouse layout to identify the best place to keep your pallet tipper, and what kind of other industrial equipment you plan to use. In addition to our extensive selection of low duty pallet tipper models, we also offer special-order modifications, specifically designed to help fulfill your needs. Read more about these options below:

-

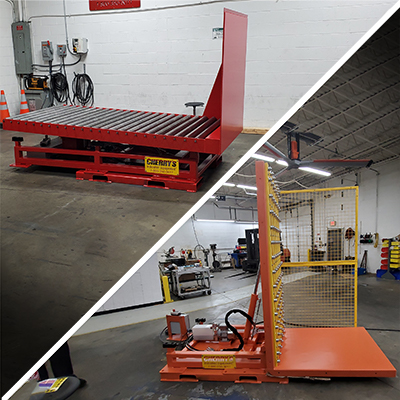

Conveyor

Automating your roll handling process increases throughput with reduced handling, less product damage, and more dollars added to the bottom line. Infeed conveyors index rolls directly into the tipper then are down-ended to a horizontal position and removed with an overhead hook. For finished products, rolls are upended onto a pallet then discharged onto a conveyor for banding. Learn more!

-

Rollers/Ball Transfer

Eliminate rolling ladders, step stools, and work platforms that cause overexertion when palletizing tall light loads above your head. A pallet tipper allows a single employee to place each box onto the horizontal table and then tip the entire load up onto a pallet for shipping. Rollers, skate table wheels, ball transfers, or UHMW material aid with box placement and eliminate stretching and reaching. Learn more!

-

V Cradle

Upend or downend spindles, paper rolls, and coils from a horizontal position to a vertical position or vice versa. A V- cradle stabilizes the roll and restricts movement while tipping. The cradles can be shallow, deep, or built for the specific size of your rolls. Powered or gravity versions are available to un-pinch the product from the pallet for easy ground level removal. Learn more!

-

Pallet Holder

Commercial printing facilities that produce pressure-sensitive labels and other slitting re-winding operations take large rolls and slit them into multiple rolls. The sheet or film is re-wound onto a core, then the smaller individual rolls are placed into a tipper (core horizontal) and upended onto a pallet. A holder secures the vertical pallet in place before the rolls are placed in the machine. Learn more!

-

Safety Gate/Ramp

When tipping certain types of products, a V-cradle isn't a viable option due to the size or shape of the object. You might be concerned about the stability of the product during the cycle but need a solution that still provides access for re-working, banding, or further operations. The special-order modification can include: D-rings with chains and hooks, pivoting safety gates, or folding ramps. Learn more!

Need to modify the standard offering?

We offer an extensive selection of options for the low duty tipping machines. If, however, none of our stock options meet your specifications, we provide custom modifications as required. The first step is to contact a representative for a consultation. We'll work with you to determine the best way to proceed and provide a detailed quote. To get started, call us at 800-350-0011 or email our office today.

We Offer Several Different Low-Duty Tippers

There are many variables ranging from sizes and weight capacity to load-in and discharge height that determines the type of low-duty tippers you need. At Cherry's Industrial Equipment, we offer multiple models to choose from including:

- LDT-2000-T1 Pallet Tipper: This 90-degree tipper is a versatile performer for low-volume turning and tipping of materials to alter the orientation or for more effortless loading on pallets. The LDT-2000-T1 low-duty tipper offers 60 seconds up-cycle and 45 seconds down-cycle times and a 2,000-pound capacity.

- LDT-2000-T2 Pallet Tipper: Similar to the LDT-2000-T1, this raised-height to near ground level 90-degree tipper streamlines the process of turning and tipping materials for quicker palletizing or to change orientation. Features include handheld two-button with E-Stop controls and a 2,000 to 4,000-pound capacity.

- LDT-2000-T3 Pallet Tipper: The unique design of this low-duty tipper with a 10-inch loading and discharge height is ideal for applications utilizing stackers and overhead cranes. Units are designed for simple and effective operation and made in the U.S.A.

- LDT-4000-T1 Pallet Tipper: Built from high-quality materials and engineered for trouble-free operation, these low-duty tippers have a positive impact on productivity. Whether you're turning paper rolls from vertical to horizontal or tipping boxes to load onto pallets, this machine is built to get the job done right.

- LDT-4000-T2 Pallet Tipper: The LDT-4000-T2 low-duty tipper offers raised, near ground-level loading and three-sided entry and operation. Features include handheld three-button pendant controls and a configurable loading table and horizontal table sizes.

- LDT-4000-T3 Pallet Tipper: The LDT-4000-T3 has a raised clearance of 10 to 12 inches off the ground for an optimal working height to tip and turn boxes laying on their side to right side up for stacking on pallets.

- LDT-4000-T4 Pallet Tipper: This low-duty tipper offers ground-level loading and unloading as well as fast cycle times from 25 to 30 seconds. The tipper is securely held in place with 12 anchors and features smooth and efficient hydraulic operation.

Low-Duty Tipper Benefits and Applications

Our low-duty tippers for sale are an excellent solution for a variety of warehouse, packing and distribution centers. When you have applications that call for tipping and turning boxes and heavy materials, having the right equipment can speed up processes and improve safety and efficiency. You benefit from fewer labor requirements and improved organization with reduced workplace injuries and product loss.

Partnering With Cherry's Industrial

We're proud to be a leading warehouse equipment supplier with over 35 years of industry experience. From competitive prices on a carefully selected product line to standing behind the equipment we sell 100%, we're the one-stop shop for businesses large and small. In addition to our selection of low-duty tippers for sale and other warehouse related machines, we also offer custom design services to meet your unique requirements.

For more information and a free quote, contact us online or give us a call at 800-350-0011 to speak with a knowledgable material handling specialist.

For more information on this see our related resources: