Our Purpose

To positively impact the lives of everyday people.

Our Niche

Engineered pallet handling solutions to improve safety and efficiency.

A focus on a safer, cleaner workplace

From the very beginning, the company's mark was on identifying common workplace pallet and material handling problems and developing new-to-market equipment designs to reduce repetitive worker injuries creating a safer work environment.

The Cherry's Industrial Story

Cherry's Industrial Equipment manufactures highly engineered pallet handling and ergonomic equipment to assist the warehouse, dock, or line worker. To create solutions for the ergonomic and safety issues found throughout the industry, Cherry’s Industrial product line expands to pallet retrievers, tippers, and dispensers. With customers’ requests for various unique applications, custom solutions soon became a standard item for the production team. Cherry’s Industrial respects the client and understands what matters.

Manufactured and assembled in the USA, Cherry’s Industrial upholds the highest quality and safety standards, continuing the great American legacy of quality craftsmanship at home.

Cherry’s Industrial offers durable, rugged, long-lasting machinery that seamlessly integrates into existing workflows or creates a new, safer, more efficient process.

Our promise to our customers is to improve our products through real-world feedback continuously, align our core values, and build to the high standards our customers deserve.

Our Story 1983 - Present

How We Made it Through 2023

Our Team

Where you work is just as important as the people you work with. Meet our team!

We see ourselves as a workplace of like-minded, kind, and talented people who love collaborating and creating customized safety equipment. Not only that, but we love to share and help teach employees about all of Cherry’s financials; that’s right, we are an open-book company, meaning we are financially transparent. We educate all employees at all levels of the organization about our business and its financial statements so they can think like owners.

We have built our company around the following GGOB three points:

- Education, so all employees can think like an owner.

- Empower; employees use education to make better decisions, acting like owners.

- Engage; employees drive the company’s results by providing bonuses, so they feel like an owner.

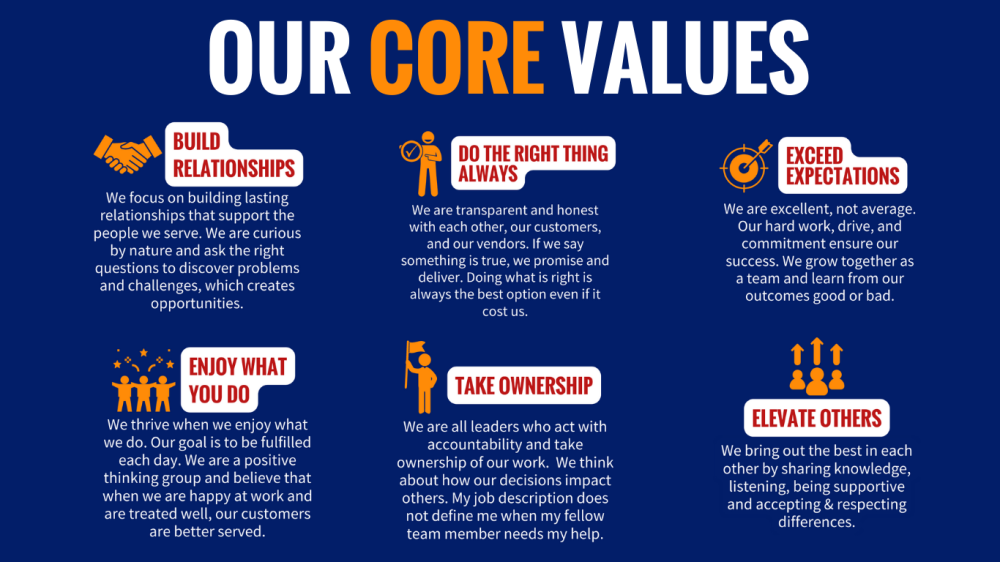

We also hold our employees, vendors, and customers to our Core Values;

As a company, we strive to lead with all core values and help bring awareness to safety and responsibility, whose impact can reach far beyond our business.

From our Customized Industrial Safety Equipment to our corporate culture and relationships, our goal is for everything we build to live up to the belief of our Core Values.

Because we know that what we do every day determines our reputation, the level of success we achieve, and the positive impact we can make on people’s health and well-being.

We want to partner with people who'll help Cherry's grow, do bigger and better things, and enhance our culture. If that's you, we can't wait to hear from you. Visit our CAREERS page!

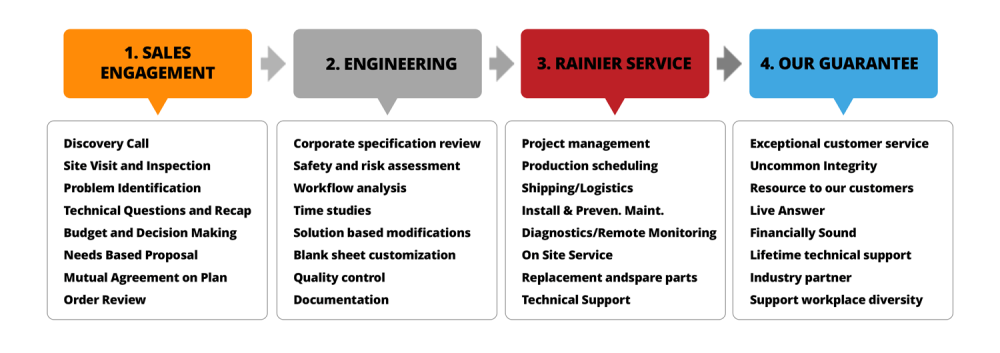

Our Process

At Cherry's Industrial Equipment, we take pride in our comprehensive process that ensures precision and client satisfaction. The Sales Engagement phase is the gateway to understanding your requirements, featuring in-depth Discovery Calls and Site Visits. The Engineering stage involves a meticulous Corporate specification review, Workflow analysis, and Solution-based modifications to tailor our approach to your needs. Our Rainier Process seamlessly manages Project management, Production scheduling, and Install & Preventive Maintenance. Backed by our Guarantee of exceptional customer service, uncommon integrity, and lifetime technical support, Cherry's Industrial Equipment is your unwavering partner in success.

Risk Assessment and Safety Services

We recognize that safety is a top priority in any warehouse environment.

Learn more about how our risk assessment and safety/ergonomic review can help you avoid costly workplace accidents and injuries.