Inline Systems

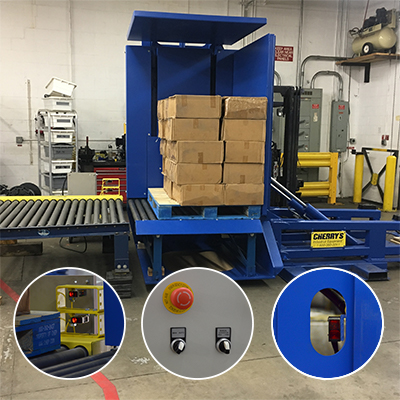

Inline Spacer Removal System Features

The keys to any line automation project is pre-planning, work flow analysis and construction/modification of an existing space. Before you make the big investment consider the following items that will effect the overall success. Other features of our Inline Systems include:

-

Function

Less handling and pallet movements for faster cycle rates

Change out bad pallets and reuse spacer quicker

Conveyor loading/unloading reduces damage and wear and tear on the machine

-

Operation

Semi automatic operation with automatic load indexing

Powered skate table to ease spacer removal

High speed power pack with soft start and stop

-

Safety

Maintenance lock out

Line mounted counterbalance valves for load holding in the event of a pressure loss

(THNTD) Two hand no die down safety controls

Special-Order Modifications

Protect employees, product, time and equipment with dock automation from Cherry’s. Inline spacer removal systems are ideal for removing freezer spacers, squaring up loads and automatic stretch wrapping in a temperature controlled space.

Add staging infeed conveyors for automatic conveyance of loads out of the freezer onto the loading dock with minimum product handling and 24/7 continuous operation. Keep your employees safe from forklift traffic on a crowded dock while reducing expensive worker compensation claims. Call or contact us today to learn more about our special order Inline Freezer Spacer Removal options:

-

Gravity In - Forklift out

Coming soon.

-

Direct Load - Power Out

Coming soon.

-

Conveyor Fed - "L" Layout

Coming soon.

-

Conveyor Fed - "U" Layout

Coming soon.

-

Conveyor Fed - "Square" Layout

Coming soon.

-

Reverse Flow

Coming soon.

Not Finding what You Need?

Custom solutions are completely within reach. At Cherry's Industrial Equipment, we offer budget-friendly custom equipment solutions that are 100% tailored to your facility's needs, no matter how unique.

All of that comes with turnkey service and speedy turnarounds. Learn more about our custom solutions today!

Freezer Spacer Removal Equipment Benefits

Inline systems and dock automation benefit every type of cold storage, 3PL and meat and poultry facilities that utilize quick freezer (QFR) freezers or traditional blast freezer cells. They allow you to quickly rotate and remove freezer spacers at a rate of 40 pallets per hour. A single forklift operator can continuously fill staging conveyors with palleted product and pick up completed, stretch wrapped loads and place into long term storage. Each system is designed with your layout and workflow in mind.

There are many benefits to investing in an Inline Freezer Spacer Removal Machine for your facility. When you layout the equipment effectively to the task, it can:

- Increase throughput: An Inline PSR System requires less staff as standalone machine does virtually without downtime or lags between loads. Forklift movements from the PSR machine to the stretch wrapper are now eliminated and replaced with automatic conveyors.

- Improve dock safety: The riskiest spot at any cold storage facility is on the loading dock with forklift traffic never stopping. Everyone knows to have their head on a swivel and look both ways before walking. The Inline System reduces traffic on the dock to unloading inbound trucks. Movements from the freezer to the dock are now handled by automatic conveyors through high-speed doors.

- Lower energy cost: Besides labor, the highest expense for a cold storage facility is energy consumption due to freezer usage. Every minute count, so once the product is temped out and the QFR or blast freezer is emptied the faster that the next batch can be frozen. The reuse of freezer spacers is essential for quick freezing. An inline system and other essential equipment for frozen food and cold storage facilities reduces this bottle neck by speeding up the freezer spacer removal process.

- Save labor costs: With nearly a 25% increase in throughput the number of employees and shifts over the course of a month a greatly reduced. Additionally, many of these employees can be redeployed to other productive tasks in other areas of the facility.

- Minimizing machine downtime: Operators can be rough on any machine especially if speed is the most important commodity which is true if the employee is paid by the piece where every spacer removed, or pallet completed counts. The operators will shake, shimmy, or bounce the basket to break up freezer bond without any regards the health of the machine. An inline system is built to be faster with controls built in to eliminate misuse by the operator.

- Reduce worker injuries: A safe worksite is more important today than ever as the workforce ages and the labor pool diminish. Our Inline PSR Systems are designed and engineered with injury prevention and cleanliness in mind. Your workers will miss fewer days of work, be happier, more productive with less workers' compensation claims or potential OSHA violations.

We understand the industry challenges

Energy consumption, high labor costs, labor shortages, high turnover, lack of employee productivity and engagement are the greatest threats to your company’s profitability.

A cold storage operator faces margin erosion from increasing customer demands, market pricing pressures, fierce competition for long term contracts and industry consolidation.

Workplace injuries and dock safety cost companies billions in damages each year. Over one-third of these injuries come from overexertion, bending and reaching, and repetitive stress over long periods. Additionally, forklifts are responsible for only 1% of all warehouse or factory accidents. However, the accidents are more serious than other types of accidents. Forklift accidents account for 10% of all physical injuries in the workplace with non-serious forklift related injuries reaching 62,00 per year in the US.

At Cherry’s Industrial, we understand the challenges that face your warehouse. We've fixed problems for warehouses for over 35 years and Cherry's has stepped up once again. We design ideal warehouse layouts for industries like Meat and Poultry to ensure that your business maximizes its productivity while minimizing employee injury and complying with HACCP regulations. Our new line of high output PSR machines and inline systems are faster and safer utilizing drives, sensors and Pld safety circuits. Ultimately users will experience less wear and tear on major mechanical components as movements are controlled. Additional misuse and damage caused by the operator are significantly reduced.

Visit the individual product pages to learn more about the benefits of Cherry's Industrial inverters and related equipment.

Choosing the correct layout

We offer an extensive selection of Inline Systems and automated dock equipment. Some things to think about as you layout your facility, dock, freezer and de-spacing room — working temperatures for the employees, cold loss between areas and the type of high-speed doors? How many pallets do you need to stage, what is your optimum daily throughput and footprint of the area?

At Cherry's Industrial, we have helped many companies with this important step. From layout, to design, integration and component and programming options. We can collaborate and recommend multiple options based on your budget, desired outcome and project timing.

Are you having trouble deciding which model, design or layout is right for your application? Our knowledgeable product specialists are here to help. It typically starts with an idea, architectural drawing of the building and a meeting with our sales and engineering staff. It might be a duplicate of a system previously built for another customer or a complete one-off customization from the ground up— just tell us what you need, and we will work with you to develop complete system with conveyors, stretch wrapper, machine that solves 100 percent of your company's problem. No more finger pointing that may come from systems integrators as we will be your single point of contact through the entire process.

Customized build, setup and installation

We don't stop there. Cherry's not only offers this equipment for sale, but we also set up and test each system prior to leaving our facility. A (FAT) acceptance test can be scheduled for a final run off and customer approval. If onsite services are required, we can get it running for you, too!

We will travel to your location, install, test, and debug the equipment, and train the employees to manage it effectively. Our local technicians are available for warranty, trouble shooting, service and ongoing freezer spacer maintenance.

Contact Cherry's Industrial Today

We offer a consultative and collaborative approach to solving the cold storage and 3PL industry issues. Why settle for a solution that solves less than 100% or your key problems. Ask us, we're here to help

Cherry’s Industrial Equipment is a leader in industrial pallet inverter technology. If this seems like the solution you’re looking for, or you would like more information, please visit us online or give us a call at 800-350-0011.

For more information on this see our related resources:

- Equipment Guide for Frozen Food and Cold Storage Industries

- Cold Storage Equipment Purchasing Guide

- Guide to Cold Storage Warehouse Equipment

- Meat and Poultry Processing Plant Layout

- Creating an Efficient Warehouse Layout

- Top Issues Facing 3PL Cold Storage Warehouses

- Industry Solutions for Frozen Food and Cold Storage Warehouse

- Industry Solutions for Meat, Poultry and Seafood Warehouse

- Industry Solutions for Distribution and 3PL