Pallet Washers

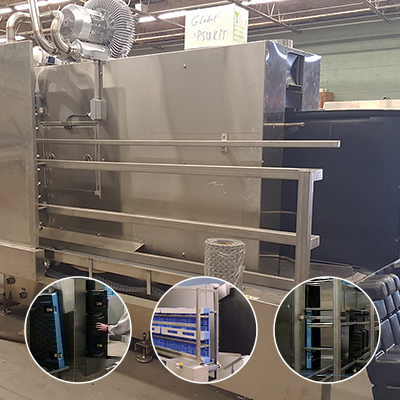

Keep your product sanitary with pallet washing systems from Cherry's Industrial. The food, pharmaceutical and chemical industries count on our stainless steel pallet washers in their daily operations. Our industrial washing equipment sanitizes wood, plastic, aluminum and specialty pallets, as well as handles washing for crates, totes, containers and freezer spacers. Protect your WIP and production areas from dust, dirt, allergens, bacteria, viruses and other contaminants.

Pallet Washer Features

When using pallet washers it's important to know that surface dust and powders will wash off with cold water however ground in dirt, blood, grease and other harmful materials will require a detergent and hot water over 185° F. Other features of our pallet washers include:

-

Function

All stainless steel construction

High impact spray nozzles to remove debris

Rinse and sanitize modules available

-

Operation

Automatic operation handling up to 200 pallets per hour

Maintain hot water with heating elements or steam

-

Safety

Essential part of a HACCP or self-auditing program

E-stops and safety rated door switches

Fully automated touch less systems available

Special Order Modifications

Pallet washers are a great investment for your warehouse because they are designed to increase sanitation and cleanliness of your regular operations. Our pallet washers are available in a number of different options and sizes to ensure that it fits the needs of your exact application while reducing the risk of contamination. Additional benefits like increased workplace safety and facilitated HACCP compliance and product safety make a pallet washer a necessary machine to incorporate into your warehouse.

Our standard pallet washers are available as either manual or automatic machines to accommodate the needs of your workplace. In some cases, Cherry's Industrial is able to design special-order modifications to our standard line of equipment to meet the specific application of your warehouse. Our experts will evaluate the flow of your facility and find the best pallet washing equipment for you. Learn more about some of our pallet washers modifications below:

-

Heat Generator

A pallet washer cleans most effectively when using hot water. To maintain a temperature throughout the cycle, strategies like immersion-style heating or piping steam into the machine so that heat is exchanged through coils in the holding tank are utilized. All modifications use programmable thermostats to set temperatures and to turn on and off at specified times of the day (like shift end). Learn more!

-

Safety Shut off

With any type of automatic pallet washer, safety is always a concern for the operator. The safety shut-off modification turns off the machine immediately when the safety circuits are interrupted, which occurs when the E-stop is pressed, an access panel door is open, main hot water tank door is open, or if the pressure at the nozzles exceeds a set PSI. Learn more!

-

Filtration

Your new pallet washer works best if the dirty water circulating through the system is constantly filtered. Special order filtration modifications include a chip basket to filter out large debris, vertical screens to filter out smaller particulates that may clog up the nozzles, or a canister-style filtration sock for a quick swap out if you are handling extremely dirty pallets, trays, or containers. Learn more!

-

Push Over Return

A standard pallet washer requires two employees for operation. One to place the empty pallet in the washer entry and another to remove the pallet at the far end after cleaning and rinsing. The push-over return modification pushes the clean pallet over onto an adjacent chain conveyor for a return trip. This allows a single operator to load and unload from the same end, significantly reducing labor dollars. Learn more!

-

Touchless

For a completely touchless operation, this pallet washer modification adds infeed conveyors and a handshake with an AGV and high-speed doors which enclose the washing room. The unit is outfitted with a de-stacker to separate individual pallets, a tipper to upend pallets for vertical washing, a tipper to downend pallets after cleaning and drying, a stacker for clean pallets, and an outfeed conveyor for pickup. Learn more!!!

Need to modify the standard offering?

We offer an extensive selection of options for the pallet washing machines. If, however, none of our stock options meet your specifications, we provide custom modifications as required. The first step is to contact a representative for a consultation. We'll work with you to determine the best way to proceed and provide a detailed quote. To get started, call us at 800-350-0011 or email our office today.

Pallet Washing Features

Pallet washers will absolutely contribute to helping your company achieve greater efficiency, safety and sanitation throughout your building. With a heavy-duty pallet cleaning option from Cherry's Industrial, you'll get:

- Fully operational control panels with wash time settings

- Independent stages to avoid cross-contamination

- High-impact spray nozzles that remove tough contaminants

- Long-lasting service and hygiene thanks to the stainless steel design

- Ability to clean multiple materials including wood, plastic and aluminum

- Varying capacities so you can wash multiple pallets at once

- Complete coverage with multiple spray nozzles

- Stainless steel rollers to manually push and pull pallets through the wash zone

- Entry and exit brushes for extra clean pallets

- Ability to add more models as your budget permits

Benefits of Using a Pallet Washing Machine

When you add a Cherry's Industrial pallet washer to your workflow, you'll experience advantages such as:

Compliance and Product Safety

Pallets can become contaminated with anything from machine coolants to oil and serve as a critical control point in sanitary environments. Anything that comes into direct contact with sensitive products and their packaging needs regular cleaning per HACCP guidelines, including pallets. Pallet washers are a fast and cost-effective way to minimize risk without eating into your productivity. They also provide better sanitation results than hand washing methods for cleaning plastic pallets.

Improved Workplace Safety

Pallet washers make a tremendous difference in improving overall safety. Built-up dust and grime on pallets brings with it the potential to introduce allergens into the working environment. A pallet washing machine can minimize the risk of Salmonella, E-coli and Listeria, keeping your team members and environment safe.

Reliable and Custom Solutions

Our team carefully selects washers for speed, efficiency and effectiveness. We sell equipment that integrates seamlessly into your workflow and can quickly process high volumes of pallets. If an off-the-shelf solution isn't right for your operation, we can provide a customized solution to fit your requirements.

Manual and Automatic Washers Available

Our inventory includes both manual and automatic pallet washers. Each equipment type has several unique benefits that suit different industries.

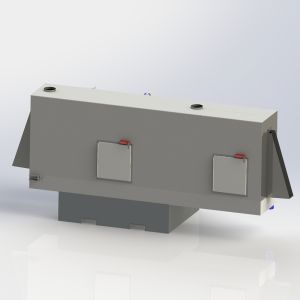

Manual Pallet Washer

A manual pallet washer, also known as a pallet washing cabinet, makes manual washing more efficient. To clean a pallet with a manual machine, insert it into the washer and let the rollers guide it through the cleaning zone. Manual washers are more economical to purchase outright, but they can typically only handle one pallet at a time. As a result, manual washers tend to suit businesses with low volumes of pallets to wash.

The benefits of a manual pallet washer include:

- Cost-effective: Businesses with smaller budgets can enjoy more effective pallet cleaning with a manual washer.

- Entry-level option: If you want to implement pallet cleaning into your workflow, a manual washer makes a great entry-level choice. You can easily test how pallet washing would fit into your operations.

- Faster than hand washing: Since a pallet washing cabinet works alongside a pressure washer, it rinses pallets more quickly and effectively. The cabinet and pressure washer handle most of the manual labor.

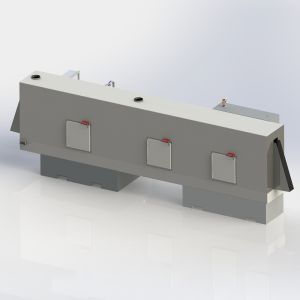

Automatic Pallet Washers

Automatic pallet washers are faster and easier to use. Some of the models we sell are capable of washing up to 200 pallets in an hour. If you have high-volume cleaning needs, investing the extra money in an automatic washer is the best way to go. Consider these benefits of an automatic pallet washer:

- Consistency and quality: Manual washing can lead to inconsistent sanitation. Automatic washers thoroughly clean pallets for maximum sanitation.

- Production level: When you handle a high volume of pallets, you need an automatic washer to keep up with production. Automatic washers enable businesses to begin handling more pallets at a time.

- Employee safety: When an employee operates an automatic washer, they monitor its loading and unloading. The machine handles the majority of the manual force, making the washing process safer.

An automatic pallet washer can greatly improve your plastic pallet cleaning operations. These machines often make up for their initial cost with a high return on investment.

Our team can help you determine the best pallet washer for your workflow when you call 800-350-0011.

How to Choose the Right Pallet Washer

Finding the right machine to meet your pallet washing needs and help create a safe, clean environment is very important. Although there's a full range of pallet washers on the market, not all are created equal. You need a unit that fits your operation to get the most benefits, so consider these questions:

- Do you require a manual or automatic washer?

- Do you need a unit equipped with a built-in rinse and dryer system?

- How large of a recirculating tank do you need?

We recommend choosing a pallet washing machine made from stainless steel. This material won't rust or corrode when exposed to water and harsh chemical cleaners, and it's the best choice for anyone searching for an automatic pallet washer. You should also search for a pressurized washer system to reduce your operating costs. A pressurized pallet washing machine limits your water use so you can clean pallets with less negative environmental effects.

Industries That Use Pallet Washers

Multiple industries use pallet washing machines to make production more efficient and safe, including:

- Automotive: Car parts are packed in pallets, crates and inlays, along with grease and metal residue. Pallets need to be completely cleaned and dried after every use. The right pallet washer removes tough grease, oil and more.

- Food: Working with eggs, dairy, poultry, fish and other kinds of meat requires frequent cleaning of fouled and contaminated pallets. A fast and fully automated pallet washing machine helps ensure optimal hygiene.

- Health care: Medical environments like hospitals require the utmost cleanliness. A large pallet washer can wash and dry pallets of all sizes to get them ready for use again.

- Pharmaceutical: Much like the health care industry, pharmaceutical plants require frequent cleaning and sterilizing. A pallet washer helps avoid product contamination and keeps your company working efficiently.

Our team partners with industries across the country to meet their handling equipment needs. For more information on how a pallet washer can help your business, call us at 800-350-0011.

Choose Cherry's Industrial for Your Pallet Washing Machines

All Cherry’s Industrial pallet washers offer tremendous value and a great return on investment. Even if you have low volume applications, we offer cost-effective rinse systems to meet your needs. Our team will help you find the best pallet washer for your specifications, and even provided custom solutions so you can address 100% of your company's sanitation requirements. Pallet washers are just one component of a clean and efficient workplace. Count on Cherry's Industrial for comprehensive solutions and expert support for all your material handling needs.

If you’d like assistance choosing the best option for you, contact our office at 800-350-0011. You can also request a quote by contacting our team online today.