Robotic / Automatic

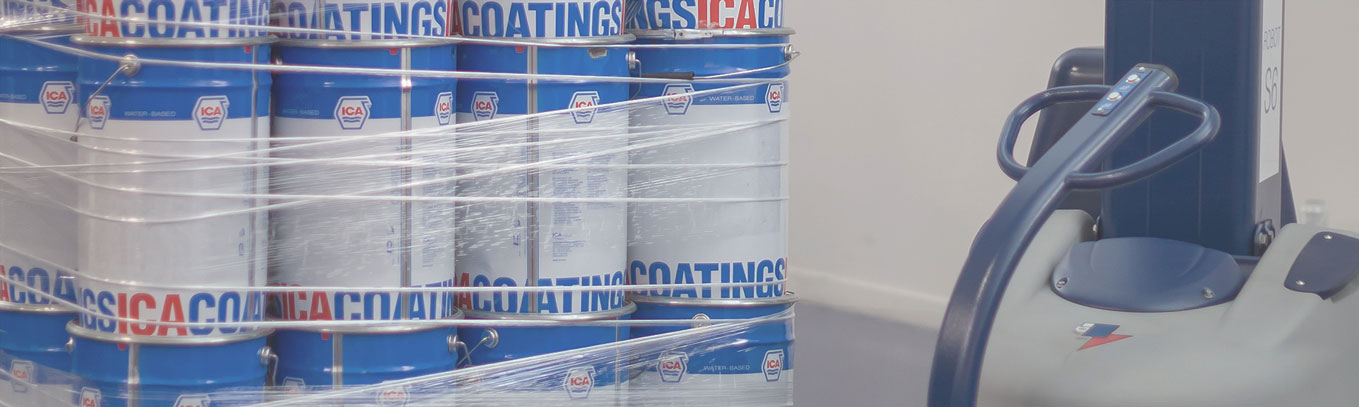

The next generation of automatic stretch wrapping equipment is available at Cherry's Industrial. Our robotic stretch wrapper selection is a portable, automatic unit perfect for large warehouses and distribution centers that hand stretch loads after order picking. Focused on efficiency in the warehouse, these automatic stretch wrappers and pallet wrappers can reduce film costs and improve load containment. In addition to its efficiency, operating this automatic stretch wrapping equipment is also simple for your staff. You position the automated unit near the pallet, tie the film off and walk away. For added safety, a safety sensor disarms the machine if necessary to prevent injury.

Robotic Stretch Wrapper Features

Robotic stretch wrappers help keep production schedules on track and can boost your customers’ satisfaction. Allow your workers to focus on other tasks! Other benefits of robotic stretch wrappers include:

-

Function

Invert or transfer different load types with variable load heights

Easily transport and load by forklift

-

Operation

Easy-to-use push-button controls accessible from the seat of the lift truck

Handrail guarding and other safety features available

-

Safety

Maintenance locks

Counterbalance valves to hold and maintain pressure

Foot obstruction photo eye to prevent

Looking for a solution for your specific application?

At Cherry's Industrial Equipment, we carry a variety of Robotic Stretch Wrappers. If our available inventory doesn't meet your specific application, we may be able to help, just ask. Contact a representative for a consultation. We will work with you to determine the best way to proceed and provide a detailed quote. Call us at 800-350-0011 or email our office today to get started.

Choose the Robotic or Automatic Stretch Wrapper That Works Best for Your Material Handling Processes

Our selection of robotic and automatic stretch wrapping equipment includes the following:

- Robot S6: This heavy-duty stretch wrapper provides six menu options, making it easy to customize its operation to the task at hand. Capable of accommodating up to 30 loads per hour, the robotic stretch wrapper can increase productivity by as much as 20 percent. The self-propelled functionality will reduce the burden on your workforce and lower the risk of workplace injuries. The stretch wrapper can also cut film consumption by more than 50 percent, which can lower your material costs and boost your profitability. The maximum load height of nearly eight feet gives you plenty of flexibility when wrapping orders for transport and shipping.

Benefits of Using Robotic/Automatic Stretch Wrapping Equipment in Your Material Handling Operation

Integrating robotic stretch wrappers into your work processes will benefit your organization in a variety of ways.By increasing wrapping speed, our equipment will help you maintain your tight production schedules and boost your customers' level of satisfaction. By holding your goods securely in place, you'll have fewer worries about damage during loading, transport and shipping. You will also experience a noticeable increase in the efficiency of your operation by saving time and reducing production and processing errors.

What's more, automatic stretch wrappers require less human labor — you'll be able to free up your workers for other tasks and lower the risk of injuries that are an all-too-common occurrence in many work environments.

Robotic Stretching Equipment Applications

Our automatic stretch wrapping equipment can add value to just about any business that ships goods via pallets. Examples include consumer products, food service, frozen foods, grocery distribution, pharmaceuticals and many others.

Cherry's Industrial: Your Best Choice for All Your Robotic Stretch Wrapping Needs

You can trust Cherry's Industrial to provide a cost-effective equipment solution that will solve 100 percent of your material handling problem — whether you're looking to improve ergonomics, safety, productivity or sanitation. You can be certain that you will receive personalized assistance every step of the way. Our knowledgeable product specialists can even work with you to customize many of our products to meet your unique functional requirements. And with our bulk pricing and simplified online ordering, we'll help you save time and money.

Give us a call at 800-350-0011 or contact us online to learn more about our robotic/automatic stretch wrapper offerings. You can also fill out and submit the quote request form found at the bottom of each product page.

For more information on this see our related resources: