Benefits of Choosing a Custom Material Handling Solution

Material handling plays a massive role in America’s economy. Practically every business relies on some form of material handling equipment. So do consumers. From the food processing industry to aviation and automotive manufacturers, the material used in production and distribution needs to be efficiently handled to satisfy consumer demands.

Efficiency is the key to profitable production and distribution. Your business goals are no different than most, except for specific needs unique to your situation. Your material handling requirements may need some particular application that can’t be found in off-the-shelf products. That’s where custom material handling solutions apply.

The benefits of custom material handling solutions are clear. Custom-designed and built material handling equipment allows you to achieve your exact business needs so you can meet company goals. That includes serving your customers on time and cost-effectively. Often, you can’t meet your goals with generic material handling products.

Why Choose a Custom Material Handling Solution?

Many companies choose to have their material handling equipment custom-designed. This tailor-made approach gets them exactly what they need to operate functionally in a systematic approach to handling every piece of material in their production and distribution chain — from raw materials to finished products.

Every piece of material handling equipment in your facility needs to do a specific job. Equipment needs to be designed exactly for that particular role. It’s difficult, never mind ineffective, to apply a piece of material handling equipment in a role it wasn’t intended for. You can’t often achieve peak efficiency with run-of-the-mill equipment. But you can with specifically designed tools and machinery. That’s one of the main custom material handling benefits.

Deciding on purchasing custom vs. standard material handling equipment requires a process. So does having it designed and built. Smart business operators are good decision-makers. These savvy business managers thoroughly understand their business needs and come up with the right solutions. Like you, they’re always looking for the right fit.

Custom-designed and built material handling equipment ensures you get the right fit. Any piece of equipment that doesn’t seamlessly fit with your operational stream is a hindrance to productivity. If it doesn’t mesh with your business needs and challenges, it’s practically worthless. You can get a vast improvement in your operation’s efficiency by adopting a custom design, built to your exact specifications.

One of the biggest benefits of having your material handling equipment custom designed is increasing workflow. It’s also called throughput. Think of the multitude of material handling steps you have in your specific manufacturing and warehousing process. How can you benefit from tweaking each material handling station and the equipment used at each place?

Likely, you’ll identify key areas or bottlenecks in your manufacturing supply and delivery chain. You’ll probably find where you have problems and inefficiency, you’re using boxed or mass-produced equipment. It doesn’t do that job properly, and that’s because it wasn’t specifically designed for that particular application. The solution is having your equipment custom-built.

Custom Material Handling Solutions for Any Industry

Most pieces of material handling equipment can be custom-designed and built. Where there’s a will, there’s a way, as the old saying goes. Cherry’s Industrial Equipment has been solving material handling problems with custom solutions for more than three decades. We work directly with you to determine your exact business needs. Our team approach ensures you’re getting precisely what you need, rather than being forced to settle with equipment that’s not truly suitable to your job.

We regularly design and build custom material handling equipment for many businesses in a wide variety of American industries. We make custom applications for automotive manufacturers and parts distributors, building supply companies and pharmaceutical producers. Professionals in the food service and beverage sectors turn to Cherry’s Industrial for custom equipment solutions. So do fertilizer and lawn care product manufacturers, as well as bakery and ingredient providers. We find custom solutions for cheese and dairy suppliers, chemical producers, pet food makers, printing and corrugated cardboard packagers, the steel stamping industry and rubber manufacturers. Even the U.S. Department of Defense has found custom solutions to their material handling problems at Cherry’s Industrial Equipment.

We can custom-design and produce many of the material handling pieces in your facility. You might need a specialized pallet inverter, or perhaps a custom stretch wrapping machine. We can modify all sorts of lift tables and pallet tippers to make sure we meet your exact custom requirements. Pallet handling is one of the most common tasks in every production and storage facility. We produce custom-built pallet upenders and inverters with pallet grippers. We even build custom-designed pallets themselves.

You’re completely in control when you choose to work with Cherry’s Industrial Equipment to have your material handling machinery custom-designed. Whether you need a single piece or an entire material handling system custom-tailored to your specifications, we have the solution. You’ll benefit in many ways with Cherry’s Industrial.

Custom Material Handling Equipment Benefits

Many business owners and managers hesitate at having their material handling needs custom-made. That’s usually because they think custom designs are expensive and time-consuming to process. But that’s not the case when you weigh the overall benefits custom work delivers. Let’s look at the main benefits of choosing a custom material handling solution:

- Efficiency is a chief benefit. When material handling equipment is custom-designed, you can clearly define its exact efficiency purpose. The piece is precision-made to address every task it’s required to do. There’s no better way to achieve peak efficiency than identifying your material handling needs and having your equipment flawlessly perform as required.

- Cost-effectiveness is another main benefit from custom equipment. You have to look at cost-effectiveness in the big picture. It’s all about return on investment. You might pay more up front to have your material handling equipment custom-designed and built, but it’s going to deliver efficiency on a large scale. That means faster throughput and lower overhead costs for labor and materials.

- Lower overhead and labor cost are primary concerns for business owners. Profitability is all about keeping labor costs under control and reducing operating expenses. Custom-designed material handling equipment will lower or even eliminate manual labor time. Custom equipment greatly reduces breakdowns and lost productivity that drives up these costs. You can also design custom equipment with energy efficiency in mind, which also saves money.

- Safety and worker strain is another major concern of material handling equipment design. Mass-market equipment is made to serve a multitude of jobs in many different locations. Many of the stock tools and machinery used in manufacturing and warehousing are made with minimal safety features. You can address this by having specific safety functions built into your custom-designed equipment. Ergonomic features are entirely possible. This greatly reduces worker strain and fatigue, which benefits your entire warehouse workforce.

- Systems integration is far easier to achieve with custom material handling equipment. Properly integrated material handling systems strive to coordinate cohesion and connectivity. Custom solutions identify all parts of your system and make sure they’re complementary to every other piece in the production and distribution chain. Customization ensures synchronicity. This weaves back to efficiency, cost-effectiveness, low overhead costs and better safety for your workers.

- Quality of equipment improves greatly when you have material handling custom designed and built to your exact specifications. This alone is an enormous benefit. When you work with an experienced custom equipment designer, you’ll choose the exact quality of parts to go into your overall design. You have the choice to select precisely what you want and not have to settle on stock components that come with pre-packaged equipment.

- Extended equipment lifecycle is a terrific benefit from custom work. By using quality components and designing your equipment for an exact purpose, you’ll gain extended time on your lifecycle over standard machinery and tools. You no longer have to rig a piece of equipment to do a non-designed task. There’s no more forcing its reach or overloading its power capacity. Again, this equates to a better return on investment when you use a custom solution to solve your material handling problems.

The Custom Material Handling Design and Building Process

Cherry’s Industrial Equipment takes your project from an idea to the dock. Our engineers work directly with you to identify your exact needs and come up with the perfect solution to improve your workflow. We can custom-engineer an entirely new product, or modify one of our existing pieces and automate it to be a good fit in your production throughput.

You’ve known Cherry’s Industrial as a company that supplies leading brands of material handling equipment. We’re also the company that stands behind our vast assortment of stocked products. But did you know we’re not just an equipment supplier? First and foremost, we’re an engineering company that specializes in solving workflow problems.

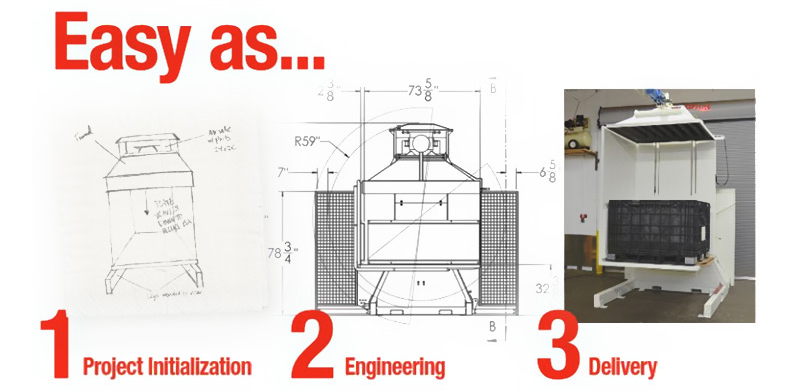

Our custom material handling design and building process is straight forward. We use three steps in going beyond what you see as stocked material handling items in our catalog. That might be taking a concept from a pallet handler or a container that’s close to what you need, but doesn’t exactly suit your specific purpose. Or, it might be a wild idea that doesn’t exist in a ready-made product. No matter how imaginative you get, our engineers can take your napkin sketch and turn it into a functioning machine. Follow us through the three design and building steps:

- Step 1 is Project Initialization. We start by discussing your project and getting a feel for what you’re after. We’ll start with learning about your current system, then we will isolate the challenges with that system. From here will focus on your goals and productivity requirements answering any and all of your questions. Next, we will begin to walk you through the engineering process and develop an approach to solving your material handling concerns. This can be straightforward for custom-designing simple pallets, or it can be highly complex for an entirely automated robotic stretch wrapping machine.

- Step 2 is Engineering. Now we’ll work from concept sketches and move on with preliminary drawings. We will identify every task you need from your custom project, and make sure that we’ve addressed every possible angle. Once we’ve got the solution worked out and a workable concept created, we will then cooperatively budget the project, so you know your costs before proceeding. Our figures are provided upfront so that there are no surprises. From here, we will recap and review all project specifications.

- Step 3 is Delivery. Once we’ve reached an agreeable price and have contract documents in place, we’re ready for construction. After a final detailed review, we generate drawings and begin component manufacturing and product assembly. We’ll keep you informed of progress and your delivery date — which depends on many factors like the material handling equipment complexity and whether specialized components are readily available. Your time frame will be reasonable, but won’t be rushed. Sacrificing quality for speed is not part of our business model. Once completed your custom equipment will be delivered to your facility. Should you choose to hire our installation team we will install your equipment and make sure the machinery is functioning at peak capacity. We’ll even help train your workers on how to use it safely.

Examples of Custom Material Handling Equipment

Having your material handling equipment custom designed and built by Cherry’s Industrial offers you the valuable benefit of experience. Our engineering team has years of experience designing and building custom material handling equipment for many different types of facilities in a variety of industries. We take our knowledge of what’s worked in other places and help you benefit from this vast experience.

You’ll know that the custom built machinery made by Cherry’s Industrial Equipment will be dependable and properly manufactured. All of Cherry’s manufactured products are made in the USA. That includes all our custom projects. You’ll also benefit other American companies by supporting their businesses. It’s a win-win in every way.

Many companies across America have turned to us to find their material handling solutions. Every one of them has benefited from Cherry’s Industrial engineering talents. You will, too. Here are several examples of satisfied clients who had custom material handling equipment designed and built by us:

- One customer needed safety specifications for the highest risk assessments. They needed to comply with a UL508a certified electrical panel with exacting specifications. Separation of high and low voltage was mandatory as was exacting guards and safety mats. This involved a team approach where company representatives worked in conjunction with the Cherry’s Industrial engineering team. Together, we created a design that exceeded safety expectations and met the client’s business needs and goals. This custom solution was an enormous benefit to our customer.

- Another Cherry’s Industrial customer needed a pallet tipper that eliminated reaching and stretching. Ergonomic performance and worker comfort were paramount to this safety-conscious company. Our engineers understood the client’s Up until then, the company was using ladders to stack boxes. This was affecting workers with muscular-skeletal injuries because they were over-extending limbs and backs. Cherry’s Industrial worked to develop a custom-designed pallet tipper that did the strenuous work for the employees. This custom project was a great benefit to everyone involved.

- Cherry’s Industrial engineers came up with another custom solution for pallet tippers. This involved a company using reusable plastic containers. They were part of a returnable program where ingredient material was continuously handled by moving from one part of the production plant to another. Loading, unloading and returning containers were done by pallet. But this procedure required multiple, strenuous handling activities while the containers were pallet-stacked. As a solution, we custom-designed a pallet tipper unique to their needs. Here, another client achieved significant benefits from our custom work.

- Collapsing corrugated cardboard containers were a big problem for another Cherry’s Industrial customer. They experienced unacceptable loss from product damage while pallets were being tipped. This was part of their material handling process and they needed a solution to prevent damage without changing their packaging material. A custom-designed pallet inverter was the perfect option. This was a combo transfer machine with moving side clamps that let pallet transfers happen without crush damage. It was also a benefit to the company’s bottom line.

- We also need to mention a scenario when a customer contacted Cherry’s Industrial for advice on speeding up their existing production process. It was another pallet-changing situation where they were using an existing stand-alone pallet retriever. Here, Cherry’s Industrial engineers designed and built a specialized pallet retriever designed to accept loads from a conveyor rather than being moved by a time-consuming truck lift. This benefited the client with improved cost-effectiveness and an efficient process.

Cherry’s Industrial Equipment Custom Solution Applications

The only thing limiting solutions from custom applications is imagination. Custom projects usually begin with a client identifying a particular material handling problem and reaching out to us for a full solution. The real benefit of working with a custom designer like Cherry’s Industrial Equipment is that we specialize in material handling solutions.

You’ll benefit from the design team’s vast experience in building and improving equipment concepts that are already proven performers. You’ll also benefit from our creativity in coming up with unique equipment applications that fit your facility’s handling challenges. That might be something as simple as a custom pallet design or something more complex like a fully-integrated and automated material handling system.

A big benefit of working with Cherry’s Industrial Equipment is that we handle so many stock items. Most standard items we carry may already be suitable for your application. In that case, Cherry’s can relatively quickly provide you a solution. If this is not the case you can assist in the customization process by first identifying any of the standard products that comes somewhat close to what you are looking for. Next, connect with a Cherry’s Industrial representative and share with them that particular product. From here you the dialogue can begin regarding further customizations you would need in order to fully meet the requirements of your application. Here is an overview on some of the stock items Cherry’s Industrial offers that can be customized to your exact specifications:

- SC Single Clamp and DC Dual Clamp Pallet Inverters can be modified for your exact application. These pallet handling devices are standard in any industry requiring inbound or outbound load transfers. We have countless customization options for either pallet inverter. Some examples include adding remote control options, pallet grippers, larger loading platforms to handle any size of pallet load your facility employs, and the list goes on.

- PSR Pallet Retrievers are very popular in the meat, poultry, and cold storage industries. They can also be customized to meet your specific requirements. Whether adding a “bump out” platform, upgrading the control console, or including a stainless steel lining, Cherry’s Industrial has the solution for your application.

- Our Low Duty Tippers are a great ergonomic tool for turning coils or rolls from either a horizontal position to a vertical position or vice-versa. These simple and amazing machines can be customized in size, capacity, and even metallic material to suit your specific requirements. Hand-held, foot-operated, or remote control options are also available at Cherry’s Industrial.

- PPW Pallet Washers are available in many configurations to meet your specific needs. For example, our PPW-2500 is available if your company is looking for a “bare bones” low-priced solution for washing pallets. If your company needs an automated solution that includes washing, rinsing, and drying pallets then Cherry’s Industrial can assist you as well. Whatever your situation let Cherry’s walk you through the steps to finding the right pallet washing solution for your facility.

- Stretch Wrapping Machines can be customized to make your pallet wrapping jobs easier and safer. The robot stretch wrappers are not as customizable as the Overhead and Turntable Stretch Wrappers but they come with programming options that can make them more efficient in stretch wrapping the varying size loads in your warehouse. When it comes to the overhead and turntable stretch wrappers, Cherry’s has an abundant array of options available from which to provide customized solutions for your specific application.

- Lift Tables can be custom modified to make your employees’ work day easier and safer.. Whether your application requires larger load platforms, higher lift ranges, corrosive resistant material, ground level loading, and so on Cherry’s Industrial will help you obtain the lift table that meets your unique criteria.

Contact Cherry’s Industrial Equipment for Custom Material Handling Solutions

By working with Cherry’s Industrial to custom design your equipment, you can be sure that you will get the best return on your investment. You’ll receive a cost-effective solution that integrates with other systems.

Custom designs are efficient, better quality and have a longer lifecycle. Their quality construction lowers your labor overhead costs. And don’t forget that custom equipment will also keep your workers safer.

To capitalize on having a custom material handling solution built by Cherry’s Industrial Equipment, contact one of our knowledgeable and helpful service representatives today.