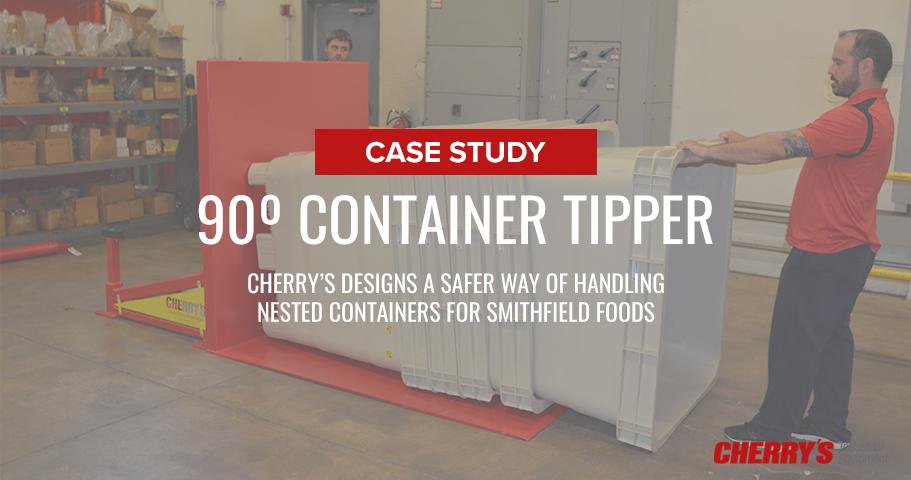

SMITHFIELD – SAFE HANDLING OF NESTED CONTAINERS WITH 90⁰ TIPPER

Re-usable plastic containers are part of a returnable program moving ingredients between production facilities and managed by CHEP within a container pool. The empty nested containers arrive at the kill plant in 8’ high stacks which is ideal for shipping but creates a problem for use. With the use of Cherry’s Industrial pallet tipper, the customer tips the stacks on its side and un-nests the containers. The empty containers move into production where they are filled with meat trimming or whole muscle and then shipped to the further processing plant. At the processing plant, the containers are emptied and then the tipper is used to re-stack the containers and returned to the CHEP pool for cleaning. CHEP pooling centers utilize the tipper both to stack and de-stack so they can wash the container and re-stack them for shipment for the cycle to repeat. With the addition of a Cherry’s Industrial pallet tippers, the employees can safely handle the containers from ground level, the warehouse space is optimized, and the warehouse operates in an efficient manner.