How New Technologies Are Changing the Way Products Are Frozen

Presently, the most common method of preserving food is freezing. A variety of different types of products can be frozen. Some include vegetables, fruit, prepared foods, pizza, entrees, yogurt, ice cream, eggs and butter, along with various kinds of meat such as fish, pork, chicken, turkey, lamb and beef.

Origins of Frozen Food Transportation & Storage

In 1880, a cargo of refrigerated meat being shipped from Australia to Britain accidentally froze. Like the invention of penicillin, the results forever changed the cold storage industry. The process was at once adopted for long-distance shipments and other kinds of storage. In the 20th century, another method of freezing known as quick or flash freezing was implemented and also discovered to be especially effective with certain types of food.

Since freezing temperatures stop bacterial growth, people found that handling food safely and quickly placing food in a flash freezer resulted in an extremely low chance of contamination. This increase in food safety reduced risk to the consumer. As a result, quick-freezing became popular in commercial food preparation.

Since living organisms are mostly comprised of water, freezing them crystallizes this water into ice. There are two factors that affect meat quality for the consumer:

- The length of time the freezing process takes.

For example, the faster seafood is frozen upon being caught the more the consumer will experience its original “wild-caught” freshness. - The microcrystalline dimension of the frozen food. When ice crystals are smaller, your food won’t be damaged as much as it would be with larger ice crystals. If, for example, the ice crystals are large then the cells of the organism can be ruptured when re-thawing.

Types of Commercial Freezing

Air Freezing of cartons of meat and prepared foods was the only type of freezing until the 1960s when Rapid Freezing came about. In rapid freezing, cartons are placed on a pallet with air spaces between them, and layers are separated with a plastic “egg crate” spacer to allow air circulation and the dissipation of heat. The most common type of rapid freezing is known as batch “blast freezing,” which is used by refrigerated warehouses and cold storage facilities.

Traditional Blast Freezer

A blast freezer is a cell or room operating at temperatures ranging at -20 to -40 degrees Fahrenheit. These blast cells use fans and blowers to direct airflow as rapidly as possible through the stacked cartons. Many designs include drive-in racking for multiple pallet positions, false ceilings, baffles and turbofans to increase wind velocity. High–speed roll–up doors are used to minimize energy loss when loading and unloading the cell.

As long as it’s not overloaded, a traditional blast freezer can typically store foods that range from chilled all the way to hot. However, if a blast freezer is overloaded with too much hot food, the heat can raise the internal temperature too high. Since blast freezers usually use a significant amount of energy, they are often utilized in commercial and industrial applications.

Tunnel Blast freezer

A Tunnel Blast Freezer is a high-density dynamic storage technology that continuously moves pallets of case-packed meats through progressive temperature zones. This tunnel system allows pallets to be placed adjacent to each other with appropriate pallet spacing between them to allow for proper airflow.

The system moves product down lanes to maximize the storage capacity of the available area while minimizing the amount of equipment inside. As the product is moved through the lanes, cold air is blasted across it. Depending on where the pallets are in the system, the air will be coming from different directions. The product stays in each zone for a specific time period before moving to the next zone.

New Innovations in Cold Storage

The latest advancements in freezing technologies still use air to rapidly freeze products but utilize pallet seals and high static fans to create negative air pressure inside a plenum. This process allows chilled air to be pulled through cases and layer spacers from the top, bottom and sides of the pallet at a rate of 200 feet per minute — almost 15 times faster than traditional blast freezers.

The benefits of these systems are numerous, including shorter freezing times, lower energy costs, no separate blast rooms, no batching and reduced forklift “touches.” Since these systems use pallet racking located in the main portion of the freezer, they are much easier to load and unload when compared to a traditional blast cell. Additionally, you can leave pallets stored in their freezing position when you don’t need the space.

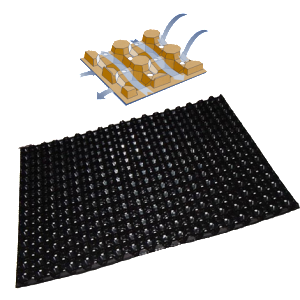

Freezer Spacers

Although great improvements in freezing technologies have been made over the past 40 years, the four types of plastic freezer spacers — Egg Crate, Maxi, Heavy-Duty Lattice and Open Profile — have continued to remain in very high demand.

These kinds of freezer spacers have all remained popular due to the advantages they provide companies that need to store frozen items. The time-saving benefits of freezer spacers, for instance, are a top advantage for those looking to cut down on utility costs. These spacers save time by allowing cold air to move between stacks of products easily, while still providing protection. Due to the unobstructed airflow, products end up with consistent and faster freezing across full pallet loads.

As an alternative to wooden freezer spacers, plastic freezer spacers are cleanable, stackable, reusable and recyclable. Since wood will absorb liquid and often isn’t entirely smooth, wood pallets can be difficult to clean, leading to a higher chance of food contamination. In contrast, plastic spacers are made out of easy to clean and sanitizable surfaces, perfect for food transport and storage.

The most popular of the plastic freezer spacers, “egg crate,” is formed of a lightweight thermoformed plastic. The “heavy-duty lattice” spacer molded of structural foam plastic is the most rugged and sturdy of all the designs. It is best used with a product that is wet and/or bloody. It is also useful in supporting boxes that tend to deform.

The latest generation “Maxi” freezer spacer augments the original with a taller footprint and heavier gauge plastic, increasing airflow through a pallet. Highly effective when used with optimized blast cell or Quick freeze plenum systems, reducing freeze times up to 17%.

Wood Versus Plastic Pallets: Which Is the Cleanest Way to Store Cold Food?

For a long time, companies largely relied on wood pallets to store, transport and stack frozen foods. However, experts who know the best cold food industry sanitation tips have since turned away from wood pallets in favor of plastic pallets.

As wood can be affected by rot, insects and mold, it’s not an ideal material for handling food due to the food contamination that can occur, harming a company’s profitability by destroying its products. The biodegradability of wood also harms the pallets’ durability, which then leads to spending money to replace them. Additionally, since wood attracts moisture and some insects, it can become a food safety hazard, and as such, is not as sanitary as plastic pallets.

Those who are looking for sterile-capable pallets that are durable, heavy-duty and easy-to-clean should look to plastic pallets. They aren’t biodegradable like wood and hold up well over time. The best plastic pallets available to consumers are approved by the USDA and FDSA for chemical handling and food processing. With this approval, you can be sure your pallets are providing an acceptable level of cleanliness for food-safety and handling.

Anyone who knows how to transport cold food cleanly knows that it starts with plastic pallets. The TC3-5 Rackable Plastic Pallet, for example, is constructed with precise welding that prevents leakage and ensures the pallets have a long lifespan. For food safety, it’s been FDA-approved and is constructed with a USDA-compliant material, which you can clean with ease.

Ultimately, plastic pallets beat out wood pallets due to their durability, design for transport and improved hygiene. They are, by far, the cleanest way to store cold food.

Cost Savings

Faster freezing means shipping your product earlier and converting it into revenue more quickly. Freezer spacers make cold storage more consistent, predictable, and cost-effective. The use of the taller high-velocity freezer spacers used in conjunction with the latest QFR Zone plenum system provides a 40% improvement (from standard cold storage methods) in removing heat from a product at a far less cost.