An Ultimate Guide: How Pallet Retrieval Equipment Builds Business Advantages

Pallet retrievers make it easier to cultivate a productive business across many industries, from grocery and other food-related companies to manufacturing, retail and warehousing. They bring safety, efficiency, speed and uniformity to the workplace.

Nearly any kind of business that requires the transportation of items could benefit from pallet retrieval systems. When items come in, they need to be organized, stored and eventually pulled for sale and shipment or delivery. This common scenario creates a lot of movements that will detract from a company’s bottom line if not well planned, timed and executed.

While there is a wide range of uses and configurations for pallet retrievers, they’re most commonly used to help transport or re-orient objects from truck to storage. Often, they will also transport those items back out for distribution. They move automatically and with exact precision to work within confined spaces and through narrow aisles with heavyweight capacity.

Cherry’s Industrial Equipment started in materials handling in 1983, and we’re eager to help people and share the pallet retriever expertise we’ve gained over the years. We’ve heard and answered many of the commonly asked questions about pallet retrievers and how different models can benefit your storage facility operations.

What Is a Pallet Retriever and How Does It Work?

Pallet retrievers enable a business to meet that universal goal of performing a quality job in an efficient manner. Pallet retrievers often work in tandem with automatic storage-automatic retrieval systems (AS/AR), pallet retrieval systems and pallet inverters.

Cherry Industrial’s pallet retrievers allow you to turn pallets sideways to safely retrieve and replace the pallet. These retrievers are an essential complement to an AS/AR, or pallet retrieval, system, which is a fully automated system that slides on tracks, moves long distances robotically and delivers and stores product. A pallet retriever and a pallet retrieval system are often paired to achieve maximum efficiency.

One of the most common uses for a pallet retriever is to raise and lower loads to a working height and often turn them to the side so that one kind of pallet can be removed and another inserted before storage or shipment. For example, loads come on a wood pallet and need to be exchanged for plastic due to food standards or weight needs, depending on the industry.

A pallet retriever clamps the load tightly at a programmable tension before it moves the load up or down to a workable height, and in some cases to its ultimate destinations. Pallet retrievers move in vertical, horizontal and lateral directions to reach high and low and move side to side.

Pallet retrieval systems usually include computer-controlled, often robotic elements working together to handle materials within precise dimensions and timeframes for receipt, transport, organization, storage and delivery. The materials usually sit in pallets, cartons, boxes or other containers.

What is a Pallet Retrieval System or AS/RS System?

Pallet retriever use and a pallet retrieval system can vary based on application, industry and your storage facility’s specific processes. A “system” is normally a machine or series of machines that make the process of product transport and management throughout the facility more efficient. Inventory and product usually get from point A to point B on pallets, and the better a pallet-handling system does its job, the more it benefits the company’s bottom line.

A pallet retrieval system usually consists of automated components, such as mast cranes, tracks, rollers, conveyer lines and other elements engineered specifically for a certain application function throughout the system. A system can include many complementary elements that together increase efficiency.

Pallet retrievers, individually and as part of a system, come in different sizes and configurations to suit a range of pallet retriever needs, from the extra-heavy loads to mini loads. These machines safely do the heavy lifts and turns as well as bring loads to a working height so that materials can be prepared for the next stage of their process.

A pallet retrieval system could also include components such as a fork lift, pallet jack/truck, rollers, wire decking, lift tables and more. These components work with the mechanical elements of the retriever to create smooth logistics. Cherry’s Industrial offers all types of pallets and slip sheets as part of those systems made of plastic, aluminum and specialty materials for hazardous chemicals.

What Are the Benefits of a Pallet Retriever System?

If you ask an owner or manager what they like best about having a pallet retriever system, each would likely have a different answer. This is because each system will have some unique benefits as well as ones realized by most users.

In the common situation where a pallet retriever is used to remove spacers or pallets from in between loads of frozen food. And, pallet retrievers can help your team remove freezer spacers about 90% faster than if performed by hand.

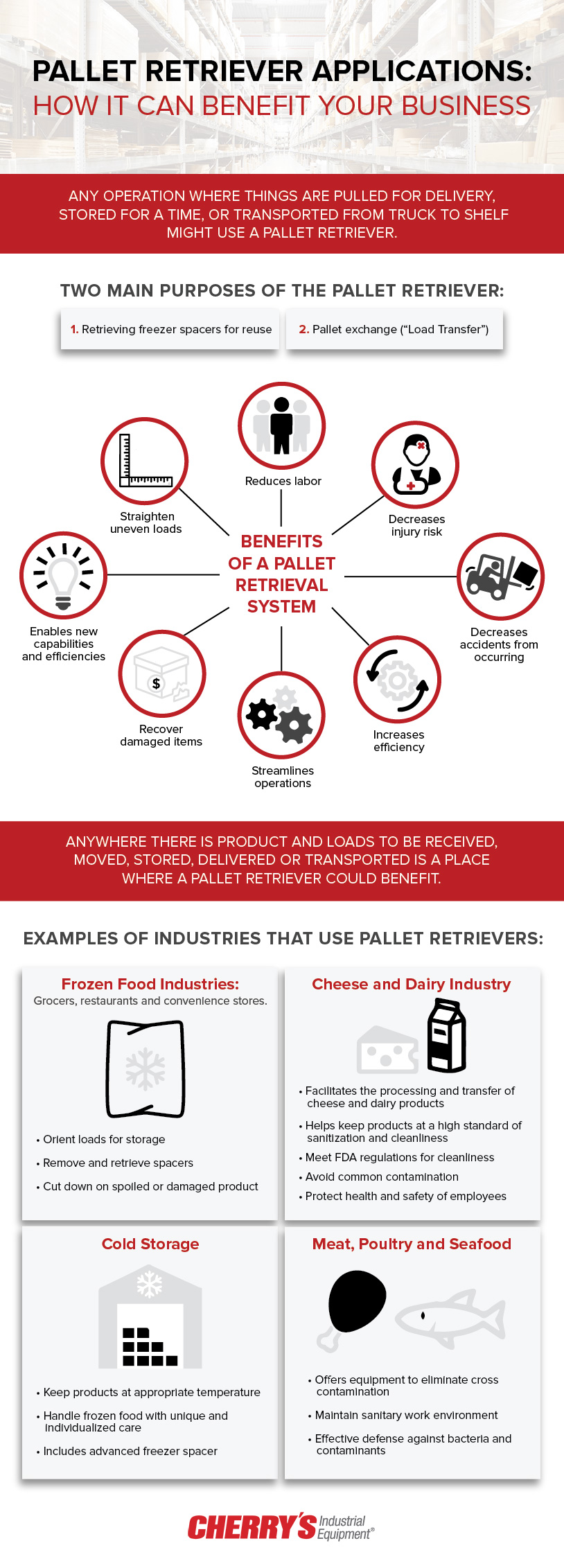

A pallet retriever creates other advantages:

- Reduces labor since it can be engineered to eliminate series of movements.

- Decreases risk of injury since it cuts out heavy lifting and repetitive motion.

- Lessens liability by creating fewer opportunities for accidents.

- Increases efficiency with precise delivery, stacking, turns and ascend-descend motions.

- Streamlines operations with consistent placement and timing.

- Improves accuracy since its operations can be engineered to exact standards.

- Expedites production transport by reducing the need for manual movement.

- Cuts down on product damage through fewer mishaps from shifting or fallen stacks.

- Maximizes space because you can stack higher and narrower.

- Provides low-noise operation to protect the hearing of those around it.

- Enables new capabilities and efficiencies since systems can be fully customized to suit a specific need.

- Reduces emissions and uses electricity efficiently.

Some businesses may seek a whole new system custom engineered to manage receiving, organizing, storing and delivering the product. Others may want to automate one segment or a few portions of their operations. Many who have paid damage claims seek to eliminate whatever labor steps tend to cause injury because proactive efforts can save big dollars.

Pallet retrievers clamp down on a load so boxes, cartons and other containers do not sustain costly damage from slides, bumps or falls. The clamp uses reliable hydraulic pressure to hold the often-stacked load in place as it’s raised, lowered or otherwise moved for transport, storage or delivery.

What Industries Use Pallet Retrievers and for What Purposes?

Any operation where things are pulled for delivery, stored for a time or transported from truck to shelf might use a pallet retriever. You will note our solutions section shows how many industries use pallet retrievers. In our case studies, there are many examples of basic and specialty pallet retriever applications.

A common usage of pallet retrievers across many industries is to eliminate the laborious or potentially dangerous steps a person would take to remove the heavier wood or plastic shipment pallets and switch them out for a lighter material. Some situations may call for a heavier pallet at the base, removal of all the spacers or some process to handle the shipping materials. Pallet retrievers are essential in businesses that must maintain the sequential order of the items in a load.

This video demonstrates how a pallet retriever works to make that pallet-removal task vastly safer, faster and easier than by hand, including rollers on the loading portion of the retriever.

A few example applications for pallet retrievers might help to tell more of the story:

A cheese supplier eyed a pallet retriever for a few years as its volume grew and manually removing the pallets became cumbersome. It was a production relief for them to get a year-end bonus in the form of a pallet retriever.

Pallet retrievers are often found in manufacturing, retail, warehouse and production settings of all kinds. Anywhere there is product and loads to be received, moved, stored, delivered or transported is a place where a pallet retriever or inverter could provide benefit.

A lot of times the need is specific to an industry or situation, such as frozen foods and spacer removal, but the concept transfers to any industry or business where the load must be taken in and moved during processing.

Why Is Ergonomics So Important?

Anyone in a business where materials are handled knows that there is an occasional inspection by the Occupational Safety and Health Administration that sometimes results in unsolicited safety advice. Bad conditions can result in reputational dings and financial fines, so most owners and managers want to stay ahead of federal standards.

Pallet retrievers and pallet retrieval systems help achieve several basic goals most businesses have: safety, organization, cleanliness and ease of movement, all of which contribute to a better bottom line and morale.

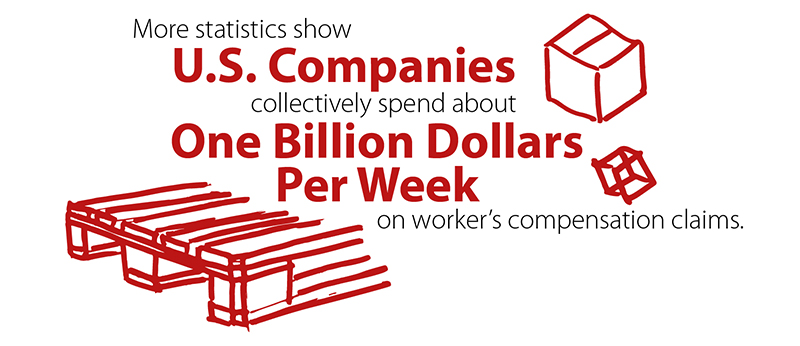

It’s no small factor that America’s workers are aging and at health risk. Employees in either category are subject to a higher risk of injury and possibly as a result, costly worker’s compensation claims.

For example, a 2015 Centers for Disease Control report states the obesity rate between 2011 and 2014 was about 37 percent. The older generation of today is perhaps the largest in number yet.

More statistics show how U.S. companies collectively spend about one billion dollars per week on worker’s compensation claims. The biggest category with that is the “overexertion of outside sources,” which includes actions that lift, push, pull, carry, hold and throw. That top category of types of worker’s compensation claims accounts for $13.79 billion and 23 percent of all claims. The category of “repetitive motions involving micro-tasks” accounts for about $1.81 billion, or 3 percent of all claims.

OSHA expounds on the types of the most commonly reported injuries, stating 33 percent of all injury cases reported are some sort of musculoskeletal disorder. Others include:

- Low back injuries

- Muscle strains

- Tendinitis

- Epicondylitis, an elbow injury

- Carpal Tunnel Syndrome

A peek into the statistics makes a good case for investment into a pallet retriever. It eliminates some of the motions that cause injury, eases motion of the job and achieves that all-important ergonomic correctness.

For examples, the CDC gives guidelines for the correct working height for loading jobs, which varies depending on the type of work. For heavy standing or loading work, it’s 28 to 35 inches high, or about 4 to 6 inches below elbow height. They call for a height of 34 to 37 inches for light standing work and 37 to 43 inches for precision jobs.

Ergonomics is quite the science, and pallet retrievers and their related systems are engineered according to the accepted data found within the science. Ergonomics are important to business not only because everyone cares about safety, but also because accidents, injuries and worker’s compensation claims cost huge dollars. Most businesses view an investment into pallet retrievers as a preventative action as much as a practical-for-now action.

What Kinds of Pallet Retrievers and Systems Are There?

The answer to this question could go on indefinitely because of the possibility for customization of everything from the manually operated base models to the fully automated and engineered system. For example, Cherry’s Industrial offers eight individual types of pallet retrievers and an endless combination of custom options.

Six of those models rotate 105 degrees and will manipulate loads of various weights and dimensions, while another is made especially for space-constrained production situations. The most frequently sold pallet retrievers serve a range of needs plus can be augmented or customized, and whole systems can be engineered completely from scratch.

Along with the standard models are accessories to make handling even easier, such as transfer systems assisted by rollers, gravity and conveyors. Controls panels are typically simple and easy to use with one or few buttons.

Businesses look for different characteristics depending on the pallet retriever purpose, but all specifications should generally be available on each.

- Loading table size

- Minimum and maximum jaw opening

- Clamping strength

- Weight capacity

- Working table height — most will be 30 ½ inches

- Operating dimensions

- Pallet-per-hour cycle rate

- Warranty

- Motor horsepower — many are 5 HP

- Available finishes — typically stainless steel or industry-approved paint

While these may be the factors people examine most often, others may be interested in other qualities, such as the shipping weight. If you’re a researcher and don’t see something about a system listed that you’d like to know, contact us and ask.

Popular Pallet Retriever Models

Details on a few of Cherry Industrial’s most popular pallet retrievers give an idea of their versatility. Generally, the standard pallet retrievers outlined below all bring a load to the ideal, ergonomic working height of 29.5 inches. Each has a working-table area of about 50 inches by 50 inches and achieve a cycle rate somewhere around 30 to 40 pallets per hour.

- The PSR-90 pallet retriever is probably most-often used to manipulate frozen loads so that the freezer spacers can be inserted or removed. It handles up to 3,000 pounds. The jaw opening of the PSR-90 runs 48 inches to 90 inches, supporting broad, heavy loads.

- The PSR-104 HD pallet retriever is frequently found in frozen-food distribution warehouses and similar settings, helping with loads at the dock and within the plant. It takes a 4,400-pound load and has a recently expanded jaw opening that opens to a minimum of 56 inches and a maximum of 104 inches.

- The PSR-110 HD pallet retriever opens to a jaw width of 62 inches to 110 inches and also has a 4,400-pound capacity. This model is commonly used to remove freezer spacers on stacked loads and the center pallet, as well as to combine pallets.

- The PSR-118 HD pallet retriever features a 4,400-pound capacity, a maximum jaw opening width of 118 inches and a minimum opening of 70 inches. This model is used for removing spacers, working with stacked loads and cubing loads from the trailer or container.

- Pallet inverters can serve similar and/or complementary purposes as the retrievers, with a 180-degree range of motion in a freestanding model. Pallets, their dispensers and much of the equipment used with them are among the other tools often found in the same environments as pallet retrievers.

What Other Equipment Works With Pallet Retrievers?

Depending on what kind of pallet retriever is at work in a plant, it consists of a few tools working together. For example, with a stand-alone pallet retriever or inverter unit, you will probably use a pallet truck or forklift to insert and remove loads. Many systems involve racking, rollers and uniform-sized bins.

While our site includes much more information about pallet retrievers and their systems, some brief summaries of their accouterment give a better idea of how they make production life easier and benefit the business.

- Pallets: Having the right material, weight, shape and dimensions in your pallet can be “the” difference your company has been looking for to fit a need, shave shipping weight, save storage space and meet other goals. We carry a big selection of plastic and aluminum pallets.

- Wire: Containers, racks and decking play integral parts in the pallet-retrieval system and can provide a tough-yet-lightweight transport and storage solution.

- Tables: A variety of work tables adds speed and ease to tasks plus ensures that the all-important ergonomic standards are being met. Spring-loaded, hydraulics, adjustability and other versatile features of the work table go hand-in-hand with tasks like removing or switching spacers between products.

- Movers: Tilters, rollers, skids, dollies, skates and jacks can all help move product and contribute as part of a pallet retriever system.

- Safety: Storage for hazardous materials, safety tape and markings, signs, guards and other equipment is a must in work areas with automated and hydraulic equipment.

What Makes Cherry’s Industrial the Best?

Cherry’s Industrial Equipment offers expertise in pallet retrieval systems and the many different components that work with them to make transport, handling and distribution faster and easier. A track record of 34 successful years in business enables us to help clients with everything from pallet retrievers and inverters to stretch wrappers and freezer spacers.

We serve more than 20,000 customers, starting with a complimentary consultation. We can supply all you need for a custom solution including on-site assessments, suggested ideas for the fix and a custom product quote. One of our promises to you is to “solve 100 percent of the problem with customized solutions.”

One of the things that sets pallet retrievers apart from the pack of other industrial equipment is how they achieve multiple benefits that boost the bottom line. One of the things that sets Cherry’s Industrial apart from other companies offering similar services are the knowledgeable people who can help clients solve problems as well as describe and explain the offered products.

We offer sales, service, parts and short- and long-term equipment rental, with extraordinary service in person and online. A good number of the products we offer are made in the United States, which is a feature many customers appreciate. In this and other ways, we seek to not only meet your needs, but to exceed your expectations.

Contact us today or give us a call at 800-350-0011. We look forward to finding the perfect pallet retrieval solution for your unique needs.